真空帮浦代理销售维修 | TEL:02-80763000 | Mail:sh.vacuum@msa.hinet.net

- 产品名称

- 关键词

- 产品型号

- 产品摘要

- 产品描述

- 全文搜索

地址:台湾 236 新北巿

邮编:23673NEA 415

Verne

不到 30 秒即可更换产品。

| TPYE/型号 | Brief | 简介 |

| NEA 230 | NEA 230 is an entirely pneumatic system for the medium pressure transport of granulates with constant product delivery feed rates. The 2 periods operating cycle resolves the problems typically associated with transporting heterogeneous materials with non-uniform grain shape. The unique technical and structural characteristics of the NEA 230 ensure continuous performance for greater productivity than a conventional venturi pump system. The innovative dual cyclonic valve system cleans the pumps and the respective utilities effectively in one minute, eliminating the downtime otherwise necessary to dismantle the individual components. The compact and versatile structure of the NEA 230 means that it can be installed quickly and easily even on existing, operational production lines. Three regulators complete with pressure gauges (for feed, transport and pinch control) let operators quickly read and, if necessary, recalibrate the pump operating pressure values. | NEA 230是一个藉由气体作动来输送颗粒原料,以适当的压力维持系统运转。 为了解决输送不均匀晶粒状的原料或特殊材质的原料,系统提供了两阶段的操作模式。 NEA 230有独特的技术和结构上的特殊设计,确保比使用传统真空泵浦吸取模式更能持续有效,具有更好的生产力。 双旋风阀系统的设计,可在短时间内清洁输送机系统的残渣,不需要拆缷组件清理,造成使用上的延误。 NEA 230紧密多功能的设计可快速安装在生产线上,进行粉体输送。操作员可藉由三个压力表调节阀(进料、输送、夹具控制)快速读取并重新校正泵浦所需的工作压力值。 |

| NEA 430 | NEA 430 is an entirely pneumatic system for the low-pressure transport of high density powders, granulates and polymers capable of continuous, high volume product feed rates. The innovative 4 periods operating cycle ensures uniform, uninterrupted delivery. The unique technical and structural characteristics of the NEA 430 ensure continuous performance for greater productivity than a conventional venturi pump system. The innovative dual cyclonic valve system cleans the pumps and the respective utilities effectively in one minute, eliminating the downtime otherwise necessary to dismantle the individual components. The compact and versatile structure of the NEA 430 means that it can be installed quickly and easily even on existing, operational production lines. Three regulators complete with pressure gauges (for feed, transport and pinch control) let operators quickly read and, if necessary, recalibrate the pump operating pressure values. | NEA 430是一个完全气动的系统,可低压输送高密度粉末、颗粒和混合物。可连续以高容量、高速率的进行粉体输送。 系统有四个操作模式,确保不间断的输送独特的技术和结构设计,比传统的真空泵吸取有更高的生产力和持续输送的性能。 双旋风阀系统的设计可在极短时间内完成清洁,省却拆缷组件所需停机的时间, NEA 430优异的性能和结构设计可很快速,容易的安装在生产线上用。 三个压力錶调节阀(用于进料、输送、夹具控制)让操作者可以快速读取并在必要时重新校正泵浦的工作压力值。 |

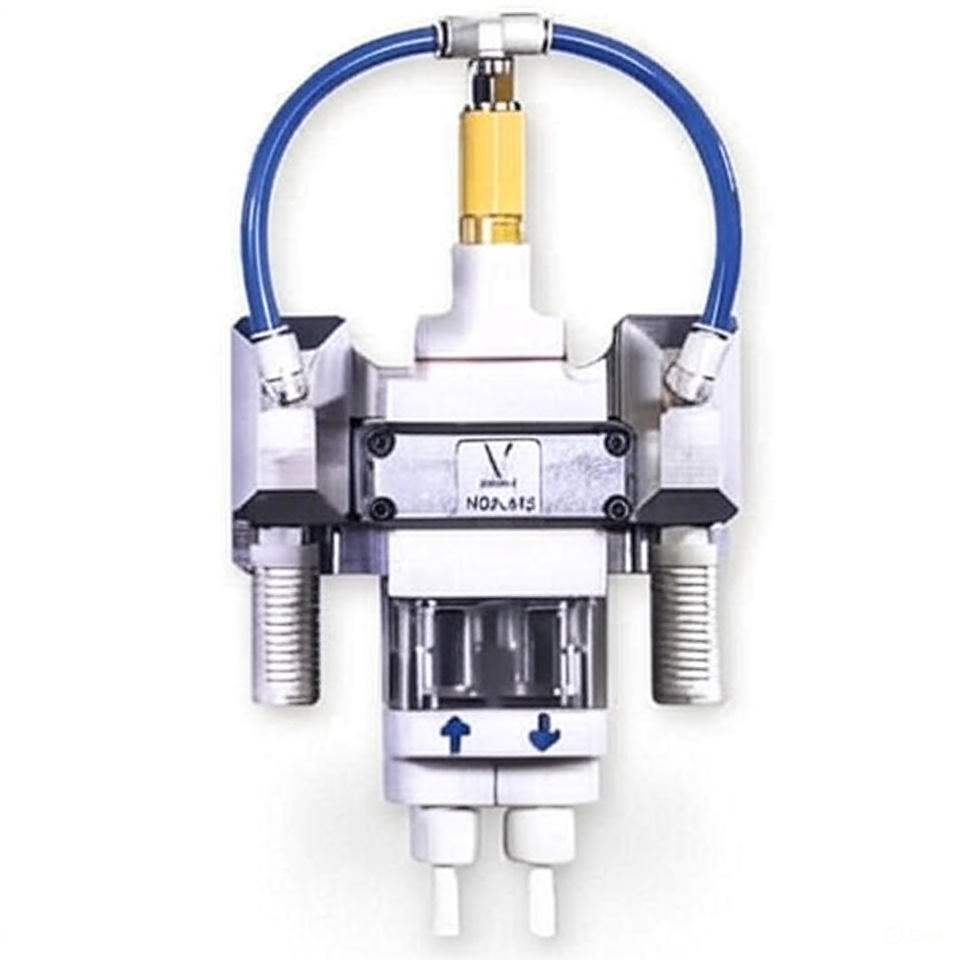

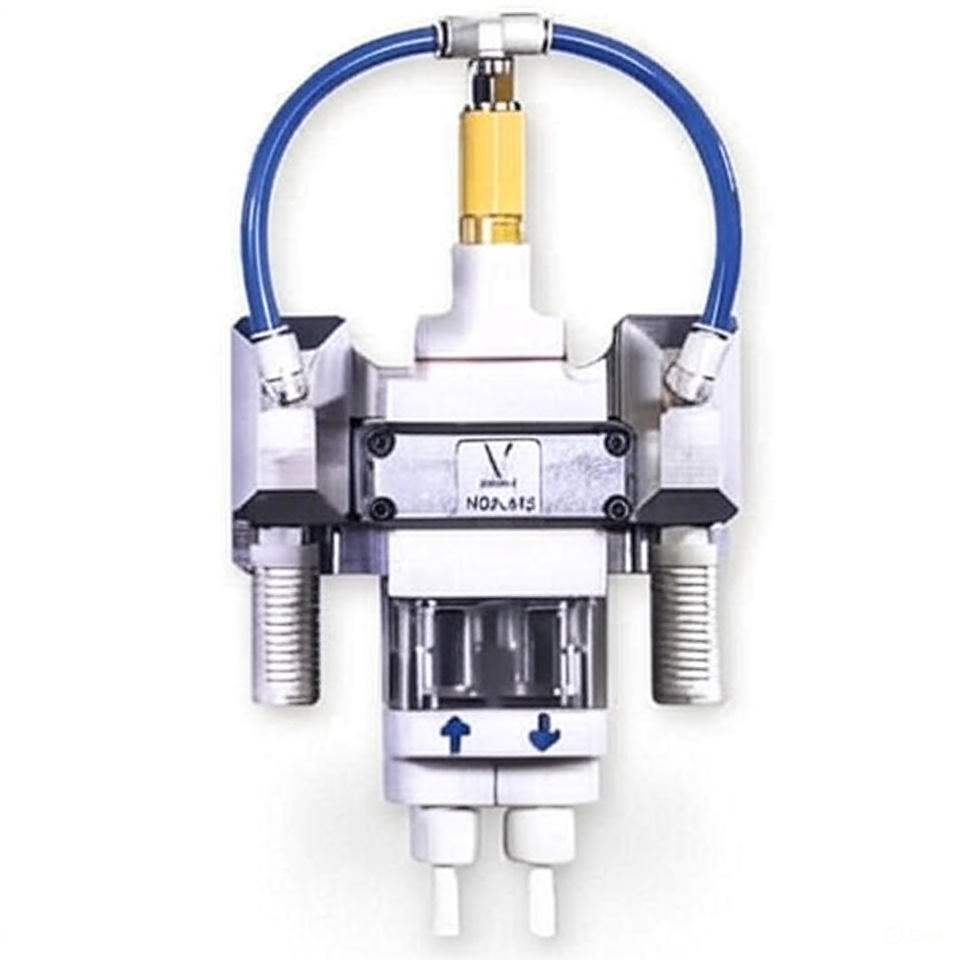

| NEA 415 | INNOVATIVE POWDER TRANSPORT SYSTEM DENSE PHASE LOW PRESSURE 4 STROKE OPERATION TRANSPORT : UP TO 600 PULSES/MIN POWDER RECOVERY UP TO 3 MT POWDER SUPPLY FROM 10 MT TO 35 MT POWDER DELIVERY FLOW CONSTANT CONTROL FROM 0 TO 400 GR/MIN POWDER DELIVERY PRESSURE CONSTANT CONTROL FROM 0 TO 5 BAR SUPPLY FLOW CONSTANT CONTROL NO ADDITIONAL AIR NEEDED IN THE SUPPLY UNIT INTEGRATED SYSTEM ALLOWS TO INVERT POWDER FLOW PRODUCT CHANGE IN LESS THAN 30 SEC. | 创新的粉末输送系统密相低压设计 四冲程操作 传输:高达 600 脉冲/分钟 粉末回收量高达 3 MT 粉末供应从 10 MT 到 35 MT 粉末输送流量恆定控制从 0 到 400 GR/MIN 输送压力恆定控制从 0 到 5 BAR 供应流量恆定控制 供应单元无需额外的空气 集成系统允许反转粉末流动 不到 30 秒即可更换产品。 |

| TROLLEY | Verne Technology has designed a fully pneumatic trolley to cater effectively and simply to the production needs of its clients. This versatile trolley allows systems and utilities to be transported simply into work environments in compliance with the ATEX directive. The NEA trolley is specifically constructed to allow the quick and easy installation of the Control Panel or of NEA 230 and NEA 430 transport systems. ●Wheeled structure for carrying containers of raw materials (boxes or drums) ●Base for mounting containers with integrated pneumatic vibrator, managed by our Control Panel ●Fluidised bed powder feeder kit managed by our Control Panel | Verne Technology 设计了一款全气动小车,以有效和简单地满足客户的生产需求。 这款多功能手推车允许将系统和实用程序简单地运输到符合 ATEX 指令的工作环境中。 NEA 手推车有专门构造,可以快速轻松地安装控制面板或 NEA 230 和 NEA 430 运输系统。 ●用于运送原材料容器(箱或桶)的轮式结构 ●用于安装带有集成气动振动器的容器的底座,由我们的控制面板管理 ●由我们的控制面板管理的流化床送粉器套件 |

销售方式:制造、批发、合作、服务、零售、出口

出口贸易条件:FOB 起运港船上交货条件

销售目标市场:台湾、香港、新加坡

询价付款方式:T.T. 电汇、L/C 信用状

义大利实验室小型粉粒真空输送机:台湾代理商

义大利实验室小型粉粒真空输送机:NEA 230

义大利实验室小型粉粒真空输送机:NEA 415

义大利实验室小型粉粒真空输送机:NEA 430

义大利实验室小型粉粒真空输送机:trolley

竞争特点

品质优良:不锈钢制造的Verne义大利-实验室小型粉粒真空输送机,粉粒体输送设备

交货迅速:产能100,预计交货期45,採用依客指定进行包装,交货港为基隆, 台北港

新产品:义大利-实验室小型粉粒真空输送机为旭豪真空科技有限公司于2022/01/01上市产品

接受独特设计或logo:可接受特别设计或LOGO,HI-VAC 粉粒体输送设备

环保产品:使用不锈钢制造的义大利-实验室小型粉粒真空输送机,已获得Verne认证,粉粒体输送设备

多样设计:旭豪真空科技有限公司提供义大利-实验室小型粉粒真空输送机的多样化设计,义大利实验室小型粉粒真空输送机

接受小额订单:旭豪真空科技有限公司可接受询价最低订购量为1件

义大利-实验室小型粉粒真空输送机接受进行原厂委託设计制造ODM

义大利-实验室小型粉粒真空输送机接受进行原厂委託代工制造OEM

义大利实验室小型粉粒真空输送机

不到 30 秒即可更换产品。

| TPYE/型号 | Brief | 简介 |

| NEA 230 | NEA 230 is an entirely pneumatic system for the medium pressure transport of granulates with constant product delivery feed rates. The 2 periods operating cycle resolves the problems typically associated with transporting heterogeneous materials with non-uniform grain shape. The unique technical and structural characteristics of the NEA 230 ensure continuous performance for greater productivity than a conventional venturi pump system. The innovative dual cyclonic valve system cleans the pumps and the respective utilities effectively in one minute, eliminating the downtime otherwise necessary to dismantle the individual components. The compact and versatile structure of the NEA 230 means that it can be installed quickly and easily even on existing, operational production lines. Three regulators complete with pressure gauges (for feed, transport and pinch control) let operators quickly read and, if necessary, recalibrate the pump operating pressure values. | NEA 230是一个藉由气体作动来输送颗粒原料,以适当的压力维持系统运转。 为了解决输送不均匀晶粒状的原料或特殊材质的原料,系统提供了两阶段的操作模式。 NEA 230有独特的技术和结构上的特殊设计,确保比使用传统真空泵浦吸取模式更能持续有效,具有更好的生产力。 双旋风阀系统的设计,可在短时间内清洁输送机系统的残渣,不需要拆缷组件清理,造成使用上的延误。 NEA 230紧密多功能的设计可快速安装在生产线上,进行粉体输送。操作员可藉由三个压力表调节阀(进料、输送、夹具控制)快速读取并重新校正泵浦所需的工作压力值。 |

| NEA 430 | NEA 430 is an entirely pneumatic system for the low-pressure transport of high density powders, granulates and polymers capable of continuous, high volume product feed rates. The innovative 4 periods operating cycle ensures uniform, uninterrupted delivery. The unique technical and structural characteristics of the NEA 430 ensure continuous performance for greater productivity than a conventional venturi pump system. The innovative dual cyclonic valve system cleans the pumps and the respective utilities effectively in one minute, eliminating the downtime otherwise necessary to dismantle the individual components. The compact and versatile structure of the NEA 430 means that it can be installed quickly and easily even on existing, operational production lines. Three regulators complete with pressure gauges (for feed, transport and pinch control) let operators quickly read and, if necessary, recalibrate the pump operating pressure values. | NEA 430是一个完全气动的系统,可低压输送高密度粉末、颗粒和混合物。可连续以高容量、高速率的进行粉体输送。 系统有四个操作模式,确保不间断的输送独特的技术和结构设计,比传统的真空泵吸取有更高的生产力和持续输送的性能。 双旋风阀系统的设计可在极短时间内完成清洁,省却拆缷组件所需停机的时间, NEA 430优异的性能和结构设计可很快速,容易的安装在生产线上用。 三个压力錶调节阀(用于进料、输送、夹具控制)让操作者可以快速读取并在必要时重新校正泵浦的工作压力值。 |

| NEA 415 | INNOVATIVE POWDER TRANSPORT SYSTEM DENSE PHASE LOW PRESSURE 4 STROKE OPERATION TRANSPORT : UP TO 600 PULSES/MIN POWDER RECOVERY UP TO 3 MT POWDER SUPPLY FROM 10 MT TO 35 MT POWDER DELIVERY FLOW CONSTANT CONTROL FROM 0 TO 400 GR/MIN POWDER DELIVERY PRESSURE CONSTANT CONTROL FROM 0 TO 5 BAR SUPPLY FLOW CONSTANT CONTROL NO ADDITIONAL AIR NEEDED IN THE SUPPLY UNIT INTEGRATED SYSTEM ALLOWS TO INVERT POWDER FLOW PRODUCT CHANGE IN LESS THAN 30 SEC. | 创新的粉末输送系统密相低压设计 四冲程操作 传输:高达 600 脉冲/分钟 粉末回收量高达 3 MT 粉末供应从 10 MT 到 35 MT 粉末输送流量恆定控制从 0 到 400 GR/MIN 输送压力恆定控制从 0 到 5 BAR 供应流量恆定控制 供应单元无需额外的空气 集成系统允许反转粉末流动 不到 30 秒即可更换产品。 |

| TROLLEY | Verne Technology has designed a fully pneumatic trolley to cater effectively and simply to the production needs of its clients. This versatile trolley allows systems and utilities to be transported simply into work environments in compliance with the ATEX directive. The NEA trolley is specifically constructed to allow the quick and easy installation of the Control Panel or of NEA 230 and NEA 430 transport systems. ●Wheeled structure for carrying containers of raw materials (boxes or drums) ●Base for mounting containers with integrated pneumatic vibrator, managed by our Control Panel ●Fluidised bed powder feeder kit managed by our Control Panel | Verne Technology 设计了一款全气动小车,以有效和简单地满足客户的生产需求。 这款多功能手推车允许将系统和实用程序简单地运输到符合 ATEX 指令的工作环境中。 NEA 手推车有专门构造,可以快速轻松地安装控制面板或 NEA 230 和 NEA 430 运输系统。 ●用于运送原材料容器(箱或桶)的轮式结构 ●用于安装带有集成气动振动器的容器的底座,由我们的控制面板管理 ●由我们的控制面板管理的流化床送粉器套件 |

销售方式:制造、批发、合作、服务、零售、出口

出口贸易条件:FOB 起运港船上交货条件

销售目标市场:台湾、香港、新加坡

询价付款方式:T.T. 电汇、L/C 信用状

义大利实验室小型粉粒真空输送机:台湾代理商

义大利实验室小型粉粒真空输送机:NEA 230

义大利实验室小型粉粒真空输送机:NEA 415

义大利实验室小型粉粒真空输送机:NEA 430

义大利实验室小型粉粒真空输送机:trolley

竞争特点

品质优良:不锈钢制造的Verne义大利-实验室小型粉粒真空输送机,粉粒体输送设备

交货迅速:产能100,预计交货期45,採用依客指定进行包装,交货港为基隆, 台北港

新产品:义大利-实验室小型粉粒真空输送机为旭豪真空科技有限公司于2022/01/01上市产品

接受独特设计或logo:可接受特别设计或LOGO,HI-VAC 粉粒体输送设备

环保产品:使用不锈钢制造的义大利-实验室小型粉粒真空输送机,已获得Verne认证,粉粒体输送设备

多样设计:旭豪真空科技有限公司提供义大利-实验室小型粉粒真空输送机的多样化设计,义大利实验室小型粉粒真空输送机

接受小额订单:旭豪真空科技有限公司可接受询价最低订购量为1件

义大利-实验室小型粉粒真空输送机接受进行原厂委託设计制造ODM

义大利-实验室小型粉粒真空输送机接受进行原厂委託代工制造OEM

义大利实验室小型粉粒真空输送机